| Installation/Work

Photos:

Take a look at the following series of

photos:

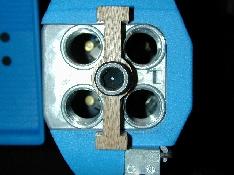

Above is a top view of the version 1+

clamp installed on a modified tool head with no dies installed. Below is

an oblique view:

No interference with the primer system or

the tool head...Now, add the dies:

Above, is version 1+ of the clamp

installed on the tool head with a set of Dillon 40 S&W dies. Note

the "close" fit between the Dillon die insert pins and the

clamp's "ears" in this

version.

|

|

Below, is a final image of version 1+

with all components installed:

Note that the powder measure system is

installed with no interference with the fastener and unobstructed access

to the clamp fastener for adjustment. Finally, take a look at the version

3 prototype clamp installed:

Remember, version 3 of the clamp design

deleted the "ears" from the clamp ends. Notice the increased

clearance around the die body lock rings. In the image above, a set of

Redding Pro Series Titanium Carbide dies and Redding die-body lock rings

are installed with the Dillon powder die and lock ring. I also checked

vertical fit with Forster Cross-Bolt lock rings. The Forster part is

slightly thicker than either the Redding or Dillon rings. Though there was

still sufficient vertical clearance to adjust the dies, I increased the

clamp "leg" dimension to add some breathing room" for

easier adjustment with the Forster rings. This new dimension is incorporated into version 3+ and

higher clamp prototypes. Additionally, the deletion of the

"ears" in version 3 allows the insert retention pins on the

Dillon seating and crimping dies to be removed and inserted more easily

and eliminates possible interference with the die when the die bodies are

set very low in the tool head.

Next...

|