|

|

This

project involves the construction of 5 speakers and a subwoofer all

at the same time, so you will see things presented from multiple

speakers and in the general order that I completed them. Adire

provides instructions for each of their kits individually just in

case my presentation gets a bit confusing.  |

| Note:

You may click on any image to see a larger (higher resolution)

version. |

Cut Sheet #1 |

Cut Sheet #2 |

Cut Sheet #3 |

| Since

I took the time to create these "Cut Sheets", I figured

that I'd make them available to the "next guy".

Sheet #1 includes the Adire

Alignment Tempest (vented) exterior cabinet, the LCC sides, LCC

mid-chamber pieces, and a single Kit 281 internal brace (to minimize

the waste a bit).

|

Sheet

#2 contains the LCC front/back, top/bottom, Tempest internal braces,

the Kit 281 tops/bottoms, and 4 more Kit 281 internal braces.

BTW, these plans are all based on

4'x8' sheets of MDF, single thickness cabinets, and a 3/32" saw

kerf.

|

Sheet

#3 contains the Kit 281 fronts/backs, one side piece, and 3 internal

braces.

Of additional note is that if you

are not doing a full 5 speaker plus subwoofer build, you might very

well have to arrange the pieces differently to get a more efficient

use if the woof.

|

Cut Sheet #4 |

Cut Sheet #5 |

Panel Stacks |

| Sheet

#4 is easy. It contains the balance of the Kit 281 side

pieces... all seven of them.

BTW, in case you haven't figured

it out yet... The sub parts are "orange", the LCC

parts are "green", and the 281 parts are

"purple".

|

Finally,

sheet #5 only has the remaining 3 Kit 281 internal braces on it.

Now, I didn't spend a ton of time

optimizing the cut sheets, but I don't think it is possible to get

it down to 4 sheets, especially considering that the above cut

sheets do not include grill frames and a few other odds and ends.

Five sheets is probably the minimum.

|

Panels

are cut and stacked in kit form". From left to right: Kit

LCC, 4 Kit 281s, and the Adire Alignment Tempest (vented).

That table is an 8' long

commercial model, and it is just about at its max gross weight!

|

LCC Crossover Boards |

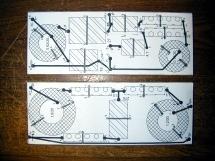

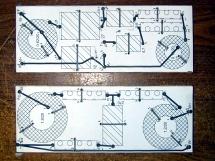

LCC Crossover Plan |

Crossover Board Drilling |

| The

Adire instructions for the Kit LCC crossover boards specify 2 boards

with dimensions of 3" x 8". I cut mine from some

scrap 1/4" "Handi-Panel" material... basically 1/4'

MDF. |

After

playing around with the printer settings just a bit, I was able to

print out the crossover placement diagrams from the instructions

(PDF file). (My printer required me to set it at 104% to get the

board outline set at exactly 3" x 8".)

Note in this image that I have

edited the layout to reflect ACTUAL component size differences,

through-hole relocations, AND through-hole sizes (in # of 32nds of

an inch).

The sizes for the lead locations

(amp, mid, tweeter, woofer) were increased some from those recorded

in the image due to the lead wire diameter being a bit larger than

anticipated.

|

Here

is just the same view after drilling the holes. I used a drill press

simply to make it easier and a bit neater. I suspect a hand drill

would work just fine.

Once again, the lead wire

locations were re-drilled to a larger size to accommodate the larger

diameter lead wire.

|

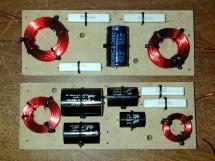

Components Secured (front) |

Components Secured (back) |

Finished Crossover (front) |

| Keeping

the layout diagram handy and properly oriented to the board, I

placed the components back on the board and secured them with small

wire ties (not the larger ones included in the kit).

Adire's instructions say to

temporarily mount them until after testing... I say,

"Wire ties are cheap! Strap 'em down." It is wayyyy easier

to test, manipulate, et al. with them strapped down.

|

Here

is the reverse side of the boards with components mounted. One thing

about using these smaller wire ties... In general, they will

snap prior to doing any damage to a component.

Note: In this image and the one

previous, you can see the 1/4" through-holes in each board.

These holes will be used to "float-mount" the boards into

the cabinet. More about that later.

|

Here

is the front view of the "finished" crossovers. i say

"finished" because they have NOT been tested yet. Yes, I

jumped the gun and soldered everything in before actually testing

them. This IS a general "No-No" in crossover building, but

I KNOW they are built according to the plan (quintuple checked

visually and electrically).

If there is a problem when I test

them in the cabinets, I'll repair/fix it then.

|

Finished Crossover (back) |

|

| Here

is the reverse side of the completed crossovers. I am NOT a

professional board assembler, so I may have not done all the

connections the "right" way. But they are all good joints.

I am actually considering building

completely new crossovers at some point with higher end

components. I would likely do one other thing differently as

well.

On all the "longer"

point-to-point connections, I will likely use good wire to make all

the connections similar to the one long run on the woofer crossover.

Simply bring the component leads straight down through the board and

solder to the wire.

|

It took me about three days to get to this point, but I was not

working full time on the project. It would have gone a LOT faster

with a larger tale saw, or a panel saw. Due to space constraints, I

have neither of those. I used a Porter Cable circular saw and a saw

board. Although you CAN get very good results using this method, it

is VERY slow. All of my cuts are within 1/32" of the

required measurement, and the vast majority of them are within

1/64".

Part two of this series s just

around the corner, so check back soon!

|